Product Details

Need to perforate the well casing while in the ground? Look no further, here is a simple answer.

The air perforator effectively perforates installed steel or PVC casing. The steel casing perforating wheel punctures rows of approximately 1/10″ x 1″ slots in wall thicknesses up to 0.450″. The PVC casing perforating wheel punctures rows of approx. 0.050″ x 0.400″. The perforating wheels are easily changed out for replacement or switching between steel and PVC casing.How a Perforator works

Designed for use with rotary drills, the perforator threads onto a standard drill string. Either through knowledge of water depth, or watching the cuttings for tell¬tale signs (like water, gravel, or sand), the perforator can be lowered to the exact depth of the aquifer.Applying a small amount of air pressure (90 PSI. any CFM) the perforator cutting wheel extends and bites into the casing wall. As the rig pushes the perforator down the casing pulls the cutter out fully (after 6″ of travel) and the perforator starts punching holes in the casing that are about 1″ long x 0.25″ wide and spaced about 1 .5″ apart.After quickly perforating a column, the drill string is returned to the starting location, air is turned off to retract the cutter. Then the string is rotated to start the next column of perforations. Good practice is to put a column in about every 4-5 inches around the casing diameter – about 4 or 5 columns for 6″ casing.Perforator Cutting Wheels

The cutting wheel is what makes perforators so convenient. As it rotates down the casing each tooth punches a hole about 1″ X 0.25″, resulting in a straight column of perforations. The cutting wheels are heat-treated and carburized to ensure durability.The rig applies the force required for the wheel to puncture the casing and a thinner blade wheel is available for rigs with less pulldown or if easier and smaller perforations are desired.Perforators also work on PVC with a special cutting wheel designed to puncture PVC using a fine tooth and a slower perforation rate.Cutting Wheel Recommendations*

| Cutting Wheel | Casing Material | Speed For 20' Section | Approx. Hole Size and Spacing |

|---|---|---|---|

| Steel (Std) | Mild Steel (0.25" - 0.375") | 15 Seconds - 105 Holes | 1" x 0.25" --- Spaced 1.5" |

| PVC | PVC Schedule 40 & 80 | 60 Seconds - 140 Holes | 0.5" x 0.2" --- Spaced 1.6" |

| Steel (Thin) | Mild Steel (0.25" - 0.375") | 15 Seconds - 105 Holes | 1" x 0.18" --- Spaced 1.5" |

* Speed is recommended, faster or slower is possible. Some users have perforated 0.5″ thick casing but it is not guaranteed; very hard material, such as drill pipe (esp. N80 Rj55) generally will not perforate. Hole size, number, and spacing will vary with cutter wear, material of casing, thickness of casing, speed, and size of perforator (4″, 6″, 10″; 4″ -20% thinner, 10″ -50% thicker). Uniformity of holes may vary down the column due to formation and material inconsistencies. The thin steel cutting wheel is only available for the 6″ perforator; it is used for thinner holes, requires less force to punch holes, and can be used on smaller Rigs (less than 50,OOO lbs pulldown). Cutter wheels wear with use and need replacement.

Most Popular

The 6″ perforator is the most popular, having an OD of 5.9″ that is ready for 6-5/8″ OD casing with a 0.250 or 0.280″ wall. When perforating thinner wall casing (0.150″) the travel stops can be removed, resulting in slightly larger holes. Adapters (shoes) are needed for larger casings (see below).

| Perforator | Top Sub |

|---|---|

| 4" | 2 7/8 API Regular |

| 6" | 3 18/2 API Regular |

| 10" (Large) | 4 1/2 API Regular |

Adapters for most casing diameters

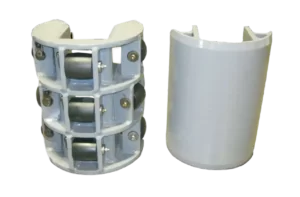

Perforators can work with casings from 4″ to 24″. Custom adapters can be provided for odd sizes, special jobs, and for sizes even bigger than 24″.Smaller diameter pipe provides less friction for perforating with slide adapters. Roller adapters reduce the force needed by about 25% so perforation can be done with smaller rigs and rollers work best for larger diameter pipes.Roller adapters can come with two different sizes of rollers (for casing diameters specified as OD or ID). Rollers for most adapters can also be changed if there is not enough force to push the Perforator down the casing.The large (10″) perforator comes standard with a 10″ slide adapter while the 4″ and 6″ perforators can be used on matched casing without any adapter.Adapters attach quickly with two bolts–once inside the well the casing snugs the adapter to the perforator.Adapter Solution Combinations

| 4" Perforator | 6" Perforator | 10" Perforator |

|---|---|---|

| 10" Slide | ||

| No Adapter | 12" Slide | |

| 5" Slide | 10" Slide | 12" Roller |

| Custom Slides | 10" Roller | 14" Roller |

| 12" Roller | 16" Roller | |

| 14" Roller | 18" Roller | |

| 16" Roller | 20" Roller | |

| Custom Adapters | 22" Roller | |

| 24" Roller | ||

| Custom Adapters |

What You Can Expect From Perforators

- The precision machined body is necessary to keep axle pins and other internal parts from becoming warped.

- Quality carbon-treated body and internal parts.

- Adapters for larger size casing are available. Slide shoes adapt to a 6″ perforator to perforate 8″ and 10″ casing and roller shoe to 12″.

- 3″ and 4″ units use adapters for 5″ casing. 6″ units use adapters through 12″.

- 10″ units use adapters up to 26″.

Operating Hints

Air Pressure

Air or water pressure of at least 40 PSI is required to set the wheel into cutting position. When the perforator is under water you must add air or water to equal the pressure outside the perforator plus at least 40 PSI. Using more pressure does not cause a problem. The perforator pop-off or developing valve opens at approximately 80 to 90 PSI. Down pressure on the drill pipe makes the wheel rotate and punch holes.

Perforator Orientation

Perforations are made when the tool is moving downward from top to bottom. Changing the configuration allows the perforator to be set up for pull-back operation.

Perforations

As a general rule, 3 to 4 columns of perforations are recommended for 6″ to 8″ pipe. For 10″ to 12″ pipe, 6 to 8 columns of perforations are recommended.

Travel Stops

Travel stops are attached to the perforator body to restrict the reach of the wheel. For casing thinner than 0.250″, remove the travel stops. This allows the wheel to extend out further for the thinner walled casing.

Cutter Wheels

Remember to retract the cutter wheel before rotating. Frequently inspect cutter wheel for wear. Inspect for excessive wear between blade and axle pin. Use PVC cutter wheels when perforating PVC pipe.

Downloadable Information

All Spare and Rebuild Parts Available

Rebuilding Service Available

3 Real life scenarios

An old, unperforated, well was putting out about 9 GPM and the owners wanted more water. Perforating a 10′ section at the bottom of the well brought the well up to 40 GPM! Perforation increased the collection area of the 6″ casing from 28 sq in to 80 sq in. Because perforation spreads out the well’s collection area, it can also help speed up recharge. Putting in the 4 columns of holes took the driller about 5 min.A driller putting in a well at a State Park was told he’d hit a gravel layer. After drilling 200′ there was no gravel and no water. He decided to use a Perforator and put 4 perforation columns in a 10′ section at 80′ deep where he’d seen black sand in the cuttings. After blowing the perforated well for a bit the well started putting out 40 GPM!A driller perforating wells for abandonment hit some casing that made the setup push his rig off the ground when he was perforating. He contacted the manufacturer and decided to try setting the perforator up for pull-back operation. He was able to keep his rig on the ground and get the job done.