Product Details

These pipe beveling and shape cutting machines are ideal to create perfect fitments for welding.

- NEW Advantage “Saddle-Type” Beveling Machine

- Durable, lightweight, hard-anodized aluminum

- Motorization kits

- Torch valve manifold block

- Double torch holder

- Storage boxes

- Shape-cutting attachments and templates

- Band-type pipe cutting and beveling machine

- Manual beveling machine head

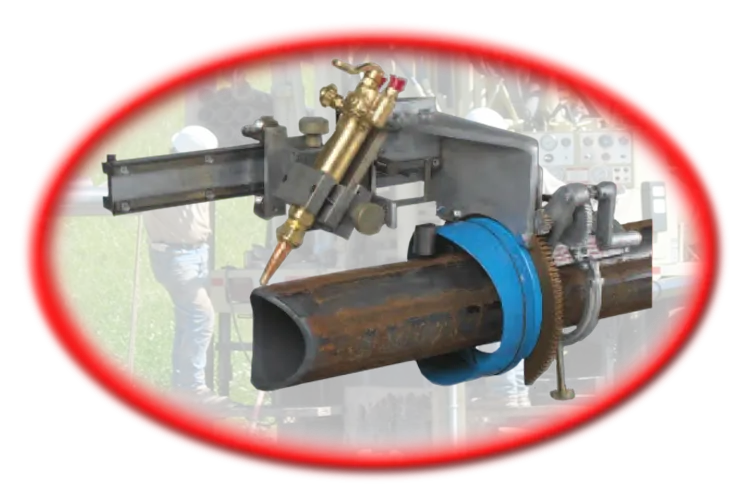

NEW Advantage “Saddle-Type” Beveling Machine

Features

- 3″, 4″, 6″, and 8″ Standard Pipe

- Easy portability

- Constructed of cast aluminum

- Rugged Heavy Duty Short Saddle Design for setting up on short pipe

- Balanced Ring Gear Assembly

- Utilizes cuboid spacers

- One Year Warranty

- Captive boomer assembly (2DH)

- Knob and Cam Assembly Standard

- Easier and Faster Set Up Time

- Competitive Pricing

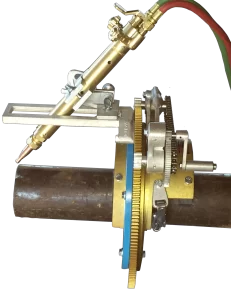

Standard Beveling Machines

Each machine is constructed of durable, lightweight, hard-anodized aluminum for easy transportation to any jobsite for cutting and beveling 2″ to 36″ diameter pipe precisely, quickly, and economically, even under the toughest conditions.

Every ring gear and saddle are precisely machined and calibrated to +/- .025 in concentricity and +/- .015 in squareness. The standard rear-mounted short saddle aids cutting and beveling in tight locations, while allowing precise back-beveling operations.

The unique “split horseshoe” design permits easy placement over pipe sections. A quick-operating boomer assembly securely locks the machine to the pipe for an entire 360-degree rotation. No repositioning is ever needed! The manufacturer’s patented Cuboid Spacer System keeps the spacers on the machine to minimize downtime.

The Pipe Beveling Machines save weld prep time and money compared to hand cutting. With easy-to-follow manuals and a few minutes of instruction, any operator can easily make accurate cuts and bevels.

How fast? For example, when using the No. 3 Standard Beveling Machine a 20″ diameter pipe can be cut and beveled in about four minutes!

| Model | Standard Pipe Size | Standard Pipe Size | Standard Pipe Size | Standard Pipe Size | Manual | Motorized | Cuboid Spacer (patented) |

|---|---|---|---|---|---|---|---|

| No. 0 | 2" | 2.5" | 3" | 4" | standard | optional | standard |

| No. 1 | 3" | 4" | 6" | 8" | standard | optional | standard |

| No. 2 | 7" | 8" | 10" | 12" | standard | optional | standard |

| No. 3 | 14" | 16" | 18" | 20" | standard | optional | standard |

| No. 4 | 20" | 22" | 24" | 26" | standard | optional | standard |

| No. 30* | 24" | 26" | 28" | 30" | standard | optional | standard |

| No. 5** | 30" | 32" | 34" | 36" | standard | optional | standard |

NOTE: Models No. 0 through No. 4 Standard Beveling Machines include the standard No.1 and 5C torch carrier assembly. The Model “C” adjustable torch holder is standard on the Model Nos. 30 and 5.

Machine prices DO NOT include torches or gas equipment.

*Model No. 30 – purchase of Model “C” out of round attachment recommended.

**Model No. 5 – purchase of Model “C” out of round attachment and motorization kit recommended.

Exclusive Standard Features

Cuboid Spacer System

Cuboid Spacer System

The patented Cuboid Spacer System relieves frustration and downtime in looking for lost spacers because the spacers never leave the machine.

Cuboid is a six-sided form with rectangular sides. Three specific thicknesses conform to different pipe sizes. Only four cuboid spacers are used to quickly set up the machine. In the past, 12 spacers were required.

The saddle of each machine and the four cuboids allow four specific pipe sizes to be cut. Each side of every cuboid spacer is clearly stamped to ensure cutting the correct pipe size. When not in use the cuboid spacers are securely housed on the back of the saddle. It’s a no-lose proposition in time-saving productivity.

Improved Saddle Design

The function and financial advantages for the customer over its competition by designing the precision saddle and ring gear as separate components.

Instead of locating the ring gear in the middle the manufacturer places the saddle behind the ring gear, greatly reducing the risk of warping the saddle while back-beveling.

The Saddle Assembly is less likely to be damaged; however, if a problem occurs, this separate component design is more economical in replacement costs.

7CS Solid Torch Holder

Now standard on all of the saddle-type beveling machines, the Model “C” Adjustable Torch Holder, the Model “C” Out-of-Round Attachment, and all Shape-Cutting Attachments, the 7CS Solid Torch Holder provides greater cutting accuracy, efficiency, and strength. A single thumbscrew secures the torch instead of hose clamps. A cotter pin makes the thumbscrew captive to the torch holder, allowing easy removal or replacement of the torch. Precise and simple to use, the 7CS means solid performance.

NOTE: The 7CS is available for retrofitting to the 5C Torch Carrier Assembly. Only two screws are needed for removal and replacement.

2DH Boomer Strap Eye Assembly

2DH Boomer Strap Eye Assembly

Forget cotter pins and S-hooks. The manufacturer offers a safer, more dependable 2DH Boomer Strap Eye Assembly. The 2DH allows the chain on the boomer assembly to quickly adjust and securely lock the machine to its respective pipe size. The boomer assembly is now a captive member of the machine.

Quality Control

Every machine is manufactured through a rigid system of quality controls, calibrated to +/- .025 in concentricity and +/- .015 in squareness during final assembly and then rechecked one last time before distribution.

Optional Accessories

Motorization Kits

For large pipe work or fabrication the motorization kits are highly recommended when 115 AC is available.

The Motorization Kits achieve precise torch speed, increased production and consistent, high-quality beveled edges with every cutting and beveling operation. Speed ranges are sufficient for most plasma-cutting applications.

NOTE: Each motorization kit has a 115VAC control box and a 90VDC reversible motor; complete with gear reduction box, mounting bracket, and gear guard. Motorization kits with instructions are available for field installation or are factory installed on new machines.

Torch Valve Manifold block (TVMB)

The Torch Valve Manifold block saves time and energy in accurate torch settings without wasting oxygen and fuel gas.

With the TVMP just adjust the torch once. A lever turns the torch on and off without altering the flame setting. Consistent, uniform, high-quality, flame-cut bevels from end to end are achieved every time! The TVMB also eliminates hose drag for even greater accuracy and productivity.

NOTE: This accessory fits all Pipe Beveling Machines. Field installation requires one hole to be drilled and tapped.

Double Torch Holder

Increase productivity by 100% with the Double Torch Holder!

It consists of one 18″ torch arm with two 5C Torch Carrier Assemblies.

After positioning the torch holders at specific bevel angle, two beveled cuts can be made in one revolution.

NOTE: For ultimate precision and control, use of the Double Torch Holder in conjunction with the optional TVMB is strongly advised.

Storage Boxes

The best protection for your machine during transportation and storage is the lightweight aluminum storage box. Storage boxes for all Models No. 0 through No. 5 Standard Beveling Machines are available.

NOTE: Boxes for Model No. 30 and Model No. 5 are available by special order only.

Model “C” Adjustable Torch Holder

Both horizontal and vertical torch movements are easily made by the Model “C” Adjustable Torch Holder with its two rack-and-pinion-driven, dove-tailed slide assemblies. Smooth, accurate torch adjustments eliminate blow holes. Even the torch height can be changed while the cutting torch is in motion.

No special modifications are needed with most torch lengths. A built-in protractor provides precise bevel angles every time. The Model “C” fits all Standard Beveling Machines, except the Model No. 0, which requires a special adapter plate.

NOTE: The Model “C” Adjustable Torch Holder fits all Standard Pipe Beveling Machines. A special adapter plate is required for the Model No. 0.

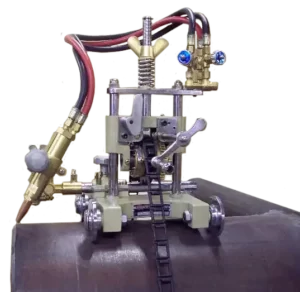

Model “C” Out-of-Round Attachment

Model “C” Out-of-Round Attachment

Cut and bevel imperfect pipe and create square ends without a problem with Model “C” Out-of-Round Attachment.

Riding on the outside diameter of the pipe, the Model “C” compensates for errors in roundness by using a spring-loaded, dove-tailed slide.

Like the Model “C” Torch Holder, the Out-of-Round features the same precise assemblies for independent horizontal and vertical torch movements. A built-in protractor provides precise forward- or back-beveling angle settings.

The Model “C” Out-of-Round Attachment fits all Standard Beveling Machines that cut and bevel 3″ to 36″ pipe. The Model No. 0 requires a special adapter when working 2″ to 4″ pipe.

NOTE: The Model “C” Out-of-Round Attachment fits all Standard Pipe Beveling Machines. A special adapter plate is required for the Model No. 0.

Shape-Cutting Attachments and Templates

Even novices to pipe cutting and beveling can achieve superior-quality craftsmanship in making saddles, Y’s, T’s, miters, and various angle cuts on all of the manufacturer’s machines with shape-cutting attachments and templates.

Even novices to pipe cutting and beveling can achieve superior-quality craftsmanship in making saddles, Y’s, T’s, miters, and various angle cuts on all of the manufacturer’s machines with shape-cutting attachments and templates.

Each custom-made prefabricated metal template is bolted to the face of the ring gear. The torch is spring-loaded against the template. While the machine rotates around the pipe the torch moves along the same path as the template. The triangular design of hard-anodized travel tubes and carriage rollers ensures lateral torch stability and smooth, consistent, horizontal torch travel during a complete revolution. Achieve accurate cuts from proven patterns every time, even when cutting miters up to 45 degrees.

When ordering the Shape Cutting Templates:

For miters – Specify machine model, pipe diameter, wall thickness, and angle of miter.

For saddles – Specify machine model, pipe diameter, wall thickness of branch, pipe diameter being intersected, and angle of intersection.

For other shapes – Please furnish technical drawings.

NOTE: Shape Cutting Attachments for Model No. 30 and Model No. 5 are available by special order only.

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

| Model No. | Net Weight (lbs.) | Recommended Usage |

|---|---|---|

| Model No. 0 | 7 | Model No. 0 |

| Standard 24" | 11 | Model Nos. 1 and 2 |

| Standard 36" | 13 | Model Nos. 3 and 4 |

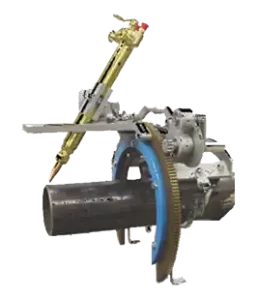

The Leader of the Band

Band-Type Pipe Cutting and Beveling Machine

The manufacturer is the leader with its Band-Type Pipe Cutting and Beveling Machine for speed, accuracy, and versatile operations on large-diameter pipe. The Motorized Beveling Head is constructed of cast aluminum. Its lightweight, compact design allows for easy one-man setup and operation. Seventeen different stainless steel bands provide a cutting range of 10″ to 96″ diameter pipe, plus special bands are available to cut pipe diameters up to 20 feet. In about five minutes a single operator can position the band and beveling machine head on 48″ diameter pipe and begin the cutting process.

The manufacturer is the leader with its Band-Type Pipe Cutting and Beveling Machine for speed, accuracy, and versatile operations on large-diameter pipe. The Motorized Beveling Head is constructed of cast aluminum. Its lightweight, compact design allows for easy one-man setup and operation. Seventeen different stainless steel bands provide a cutting range of 10″ to 96″ diameter pipe, plus special bands are available to cut pipe diameters up to 20 feet. In about five minutes a single operator can position the band and beveling machine head on 48″ diameter pipe and begin the cutting process.

These machines have the following features:

Stainless Steel Bands

- Economical – each band overlaps numerous pipe sizes

- Automatically compensates for over- and under-sized pipe

- Unaffected by dope or coating on the pipe

- Assures accuracy – overlapping squares up the band

- Flexibly conforms to out-of-round pipe

NOTE: Each band includes a drive chain and a coupling.

Motorized Beveling Machine Head

Motorized Beveling Machine Head

- Rugged, lightweight cast aluminum chassis

- Easily portable at only 18 lbs.

- Works with all of the manufacturer’s stainless steel bands

- Variable speed control box with forward and reverse capabilities

- Standard 90 volt DC motor

- Speed ranges – 2 ipm to 24 ipm

- 220 volt optional

- Plasma speeds optional

NOTE: The Motorized Beveling Machine Head includes a 115 VAC control box, DC reversible motor, torch holder and works with all band sizes. It DOES NOT include cutting torch and tip.

Manual Beveling Machine Head

Rugged, lightweight cast aluminum chassis

Rugged, lightweight cast aluminum chassis- Easily portable at only 20 lbs.

- Works with all of the manufacturer’s stainless steel bands

- Fitted with an 8.5′ flexible drive cable and crank handle

- No electricity required

NOTE: The Manual Beveling Machine Head includes an 8.5 foot flexible drive cable, torch holder and works with all band sizes. It DOES NOT include cutting torch and tip.

Band-Type Machine Storage Box

The optional Band-Type Machine Storage Box is ruggedly constructed, making it a safe storage place for one beveling machine head and several bands, plus torches, cutting tips, strikers, tip cleaners, and more.

NOTE: The Storage Box provides storage for one beveling machine head and multiple bands.

Chain-Type Pipe Machine

4″ to 24″ pipe capacity

Additional chain links can be purchased for larger pipe sizes

Cutting torch and three tips included

Control valves for fuel gas, pre-heat, and cutting oxygen included

Manual drive (brass worm gears provide smooth motion)

Torch holder racks in, out, up, and down

Torch holder can be positioned at any angle

NOTE: A handy clutch allows quick rotation of the machine around the pipe to verify position and square up the chain.

Rugged, lightweight cast aluminum chassis

Rugged, lightweight cast aluminum chassis