Product Details

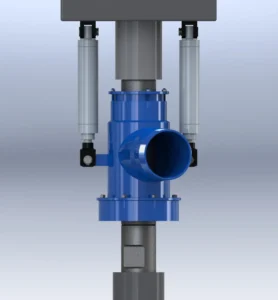

Two air cylinders attach the diverter to the rotation head, and are operated by a remote pneumatic valve on the control panel. The diverter can be raised or lowered by the operator to expose the top of the drill tube, or add down pressure to the casing if needed. In the event that the casing turns, the lower portion of the diverter will revolve on its bearing.

Xs pneumatic diverter 6″ – 8″

Specifications:

- Drill rod: 3 1/2″ 4″, and 4 1/2″

- Weight 95 lbs.

- Height: 17″

- Casing Capacity: 6 5/8″ to 8″ – up to 10 3/4″

with special adaptor - Seal: 2″ x 1″ rubber ring

- Outlet: 6″ NPT

- Reducer: 6″ NPT to 5″ NPT

- Hammer: 4″, 5″, 6″, or 8″ hammer

- Maximum pressure: 100 PSI

- Tapered bottom bearing portion: 11″ O.D.

Xs pneumatic diverter 10″ – 12″

Specifications:

- Drill rod: 4 1/2″, 5″, and 5 1/2″

- Weight 145 lbs.

- Height: 23″

- Casing Capacity: 10 3/4″ to 12 3/4″

- Seal: 2″ x 1″ rubber ring

- Outlet: 6″ NPT

- Hammer: 6″ or 8″ hammer

- Maximum pressure: 100 PSI

- Tapered bottom bearing portion: 14 1/2″ O.D.

Other sizes available on request.

The Xs diverter kit comprises a diverter assembly, two air cylinders and a control box, and miscellaneous hose and fittings. The control box is to be mounted (bolted or welded) at the drill rig’s control panel and within easy reach of the operator. The diverter and cylinders are to be mounted beneath the Rotation Head drive spindle.

Installation of the Diverter The method of installation of the diverter and air cylinders depends on the type of drilling rig it is being fitted to.

The method of installation of the diverter and air cylinders depends on the type of drilling rig it is being fitted to.

Firstly, attach the 20″ saver sub to the rotation head and tighten. Note the saver sub should be smooth and free of wrench flats.

Next, position the diverter over the saver sub, exposing the bottom thread and 1″ – 2″ of the sub is below the diverter. (This enables the sub to be clearly visible when adding tubes during the drilling operation.)

Connect each rod end of the cylinder (in the closed position) to the diverter with the pins provided and align the cylinders vertically upward to find where they can to be attached to the rotation head frame. (Some bracket work may be necessary at this point.)

If the cylinders do not reach the underside of the rotation head, you may have to raise the lifting arms on the diverter itself; this also allows the diverter to be rearranged if necessary to make the discharge port point in the desired direction. It is recommended that the yokes of each end of the cylinders should be mounted at 90 degrees to each other.

The anti-rotation arm should now be fitted in such a position contacting the left hand side runner of the mast. Once the desired position is ascertained, the bracket should be properly welded.

Note: The lifting brackets on the diverter and the anti-rotation bar are not factory-welded and ready for use, but simply placed and tack-welded to show one possible position.

Maintenance

Periodically, as required, the top seals on the diverter may need adjusting to compensate for leakage (the seals can be tightened with the four adjusting bolts provided.)

When starting to drill, the casing may turn for the first 20 – 40 feet of drilling due to lack of ground friction. To accommodate this undesirable event, the bottom of the diverter has a rotating bearing that may need to be removed and cleaned from time to time.

Air Circuit The control panel needs to be mounted within easy reach of the operator (a popular location is on top of the drill rig’s control panel).

The control panel needs to be mounted within easy reach of the operator (a popular location is on top of the drill rig’s control panel).

An air supply hose from the drill rig’s compressed air circuit to the rear of the control box is needed to power the assembly. This supply hose must be rated to accommodate the high pressure generated by your compressor.

Connect the cylinders together with flexible hose, coupling both top ports in parallel to a common tee and both bottom cylinder ports in parallel to a common tee. This causes the cylinders to act in unison.

It is advantageous to install quick couplers at these common supply points (tees) so that the diverter is easily removed when not needed. One air supply hose for the lifting side of the cylinders is connected with a quick coupler to the tee joining them both, and the same for the downthrust side.

These two supply hoses are then routed along the hammer supply line up and down the side of the drill mast, fastening them to the large hose with cable ties.

The other ends of the hoses are then attached to the up/down lever on the control panel. The control panel air pressure regulator should then be set at 100 psi, and the control lever should now raise and lower the diverter.

Discharge Hose

The discharge hose should be attached to the outlet to direct the drilling debris away from the operator. In most cases a short discharge hose is adequate, but should a long discharge hose be needed, care should be taken to secure the loose end to a solid object to prevent hose whip.

Warning: Unsecured long discharge hoses are dangerous. Any long discharge hose should be well secured before drilling.

We recommend the following discharge hoses be used:

- 5″ hammer: 4″ or larger discharge hose

- 6″ hammer: 5″ or larger discharge hose

- 8″ hammer: 6″ or larger discharge hose

Control Box

The control box is to be mounted (bolted or welded) at the drill rig’s control panel and within each reach of the operator.

Description:

Metal box 10″ x 10″ x 6″

4/3 close center valve 3/8″ NPT

Regulator 3/8″ 125 PSI

Plate-mounted dial

| Quantity | Description |

|---|---|

| 100' | Multi-purpose 3/8" Hose |

| 3 | Te 3/8" NPT Box |

| 19 | 3/8" Pin NPT x 3/8" Push-lok |

| 2 | Coupler |

| 2 | 3/8" Nipple |

| 2 | Fitting |

| 2 | Hex Nipple 3/8" Brass |

| 4 | Elbow pin-box NPT Brass |

This kit includes all fittings and the hose needed for the installation of the Xs pneumatic diverter.